Transforming Manufacturing Intelligence:

Unified, Real-Time Analytics & AI Platform on Databricks

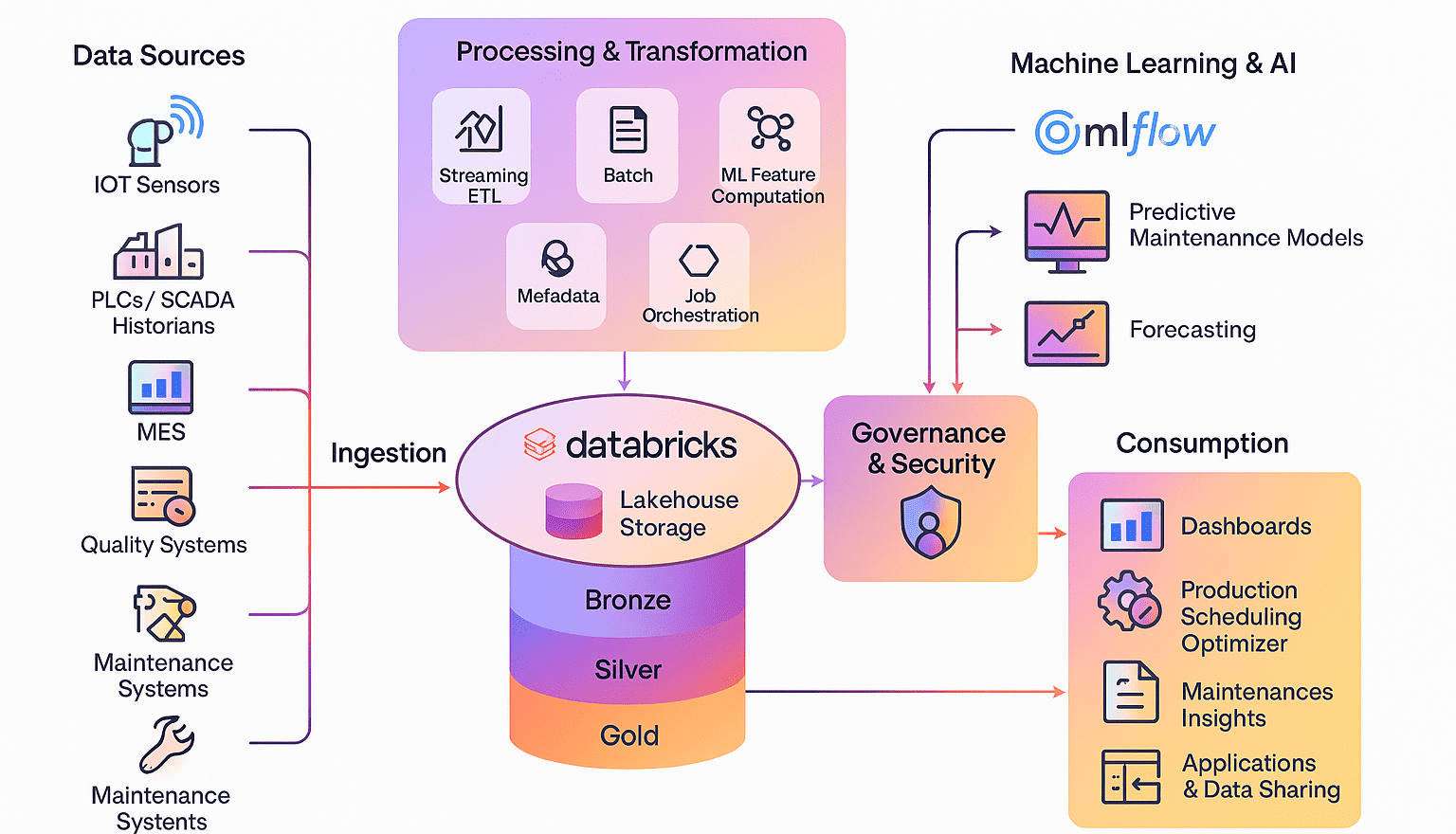

A global manufacturing enterprise operating multiple geographically distributed plants was struggling with data silos, fragmented systems, and rapidly expanding IoT sensor data. With limited analytics capabilities, the organization lacked real-time visibility into machine performance, production bottlenecks, and predictive insights for maintenance and scheduling.

Intellify partnered with the client to build a modern, unified analytics and AI platform on Databricks—breaking down silos, enabling real-time data processing, and unlocking actionable intelligence across operations.

Key Results

%

reduction in unplanned machine downtime

%

faster production cycle insights

%

reduction in manual analytics efforts

Goals

-

Break down siloed data spread across individual plants, ERP, MES, and IoT systems.

-

Build a scalable platform capable of ingesting and processing high-volume IoT sensor data in near real time.

-

Enable advanced analytics and AI/ML use cases such as predictive maintenance, energy optimization, and production scheduling.

-

Create a governed, democratized analytics ecosystem for plant managers, operations, and data science teams.

Solution

-

Implemented a unified Delta Lake architecture to consolidate ERP, MES, historian, and IoT data into a single governed platform.

-

Built streaming ingestion pipelines using Auto Loader and structured streaming to process millions of sensor signals per day in real time.

-

Developed predictive maintenance and anomaly detection models using Databricks ML runtime, accelerating data science experimentation.

-

Designed a production scheduling optimization engine leveraging historical production runs, machine availability, and sensor data.

-

Created role-based operational dashboards providing real-time equipment health, downtime patterns, and plant-wise KPIs.

-

Established end-to-end governance and CI/CD automation with Unity Catalog, data quality checks, and automated deployment workflows.

Results

35%↓

Reduction in unplanned downtime

by proactively identifying machine failures before they occurred.

50%

Faster Insight Generation

through real-time streaming pipelines that empowered quick decision-making.

70%

Enhanced Data Transperancy

via a unified Delta Lake enabling cross-plant analytics and benchmarking.

40%

Reduction in Manual Analytics Efforts

with automated pipelines and standardized data models.

- Unified Platforms: Simplified operations and reduced silos, enhancing cross-regional collaboration.

- Scalable Architecture: Supported seamless onboarding of new data sources and scaled to future requirements.

- Cost and Time Efficiency: Reduced manual effort through automation and consolidated tools for cost savings.

- Comprehensive Governance: Delivered robust compliance and access control mechanisms.

Get Your Modern Data Platform Assessment Done Today with Intellify Experts!

Check Out Some of Our Recent Work

Power BI solution for a leading manufacturing company

Microsoft BI solution for leading African Bank